Revving Up Innovation: EV Companies Seek Solutions Amid Microchip Crisis

Microship shortage in EV industryTable of Contents

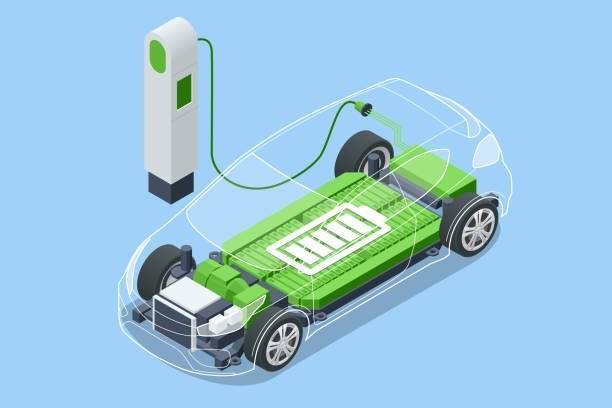

In the dynamic landscape of electric vehicles (EVs), innovation drives progress. However, the industry faces a formidable challenge: the microchip crisis. As semiconductor shortages disrupt production lines, EV companies are propelled to seek innovative solutions. In this article, we delve into the strategies employed by EV manufacturers to navigate the microchip crisis while driving forward the innovation that defines the sector.

Unveiling the Microchip Crisis

Microchips, the unsung heroes of modern technology, power the intricate systems of electric vehicles. From managing battery performance to enabling autonomous driving features, these tiny components play a pivotal role in shaping the future of mobility. Yet, the global semiconductor shortage, fueled by factors such as increased demand and supply chain disruptions, has cast a shadow over the EV industry.

The Impact on Innovation

- Production Disruptions: EV manufacturers are facing production delays and supply chain bottlenecks due to the microchip crisis. The scarcity of semiconductors has forced companies to reassess production schedules and adapt to fluctuating chip availability.

- Innovation Constraints: The microchip shortage poses challenges to innovation within the EV sector. R&D initiatives aimed at enhancing vehicle performance and introducing next-generation features may experience setbacks, hindering the pace of technological advancement.

- Market Dynamics: The ripple effects of the microchip crisis extend beyond production lines, impacting market dynamics and consumer choices. Limited availability of certain EV models and potential price increases may influence consumer preferences and purchasing decisions.

Strategies for Overcoming the Crisis

- Supply Chain Optimization: EV companies are optimizing their supply chains to mitigate the impact of semiconductor shortages. Diversifying supplier networks, prioritizing critical components, and implementing robust inventory management systems help navigate through the crisis.

- Adaptive Manufacturing: Flexibility is key to overcoming production challenges posed by the microchip crisis. EV manufacturers are adopting agile manufacturing practices, adjusting production schedules, and leveraging alternative sourcing strategies to maintain operational continuity.

- Technological Innovation: Despite the hurdles, the spirit of innovation remains alive in the EV industry. Companies are investing in research and development to explore alternative materials, optimize chip usage, and develop innovative solutions to address semiconductor shortages.

Navigating Towards Solutions

In the face of adversity, the EV industry is harnessing the power of innovation to navigate the microchip crisis. Collaborative efforts between manufacturers, suppliers, and policymakers are underway to address supply chain vulnerabilities and bolster resilience. From reimagining production processes to investing in next-generation chip technologies, the pursuit of solutions is driving the industry forward.

In conclusion, the microchip crisis presents a formidable challenge to the EV industry, yet it also serves as a catalyst for innovation and resilience. Through collaborative efforts and a relentless pursuit of solutions, EV companies are poised to overcome this crisis and continue driving forward the innovation that defines the sector.

FAQs:

How long is the microchip crisis expected to last?

The duration of the microchip crisis is uncertain, with experts predicting it may persist for several months to years, contingent upon global supply chain dynamics and market forces.

How are EV manufacturers prioritizing chip allocation amidst the crisis?

EV manufacturers prioritize chip allocation based on critical functions such as battery management, powertrain control, and safety features, ensuring essential vehicle functionalities are maintained.

Are there any long-term solutions to prevent future semiconductor shortages?

Long-term solutions include investment in domestic semiconductor production, diversification of supplier networks, and collaborative efforts to enhance supply chain resilience and transparency.

How does the microchip crisis affect consumer options and pricing for EVs?

Consumers may experience limited availability of certain EV models, longer wait times for delivery, and potential price increases as manufacturers grapple with production constraints and rising costs.

What steps can consumers take to mitigate the impact of the crisis on their EV purchase?

Consumers are encouraged to stay informed about production updates from manufacturers, consider alternative vehicle options, and communicate with dealerships for personalized assistance and guidance.