The Power Gridlock: Inside the Microchip Shortage Choking the EV Industry

Microship shortage in EV industryTable of Contents

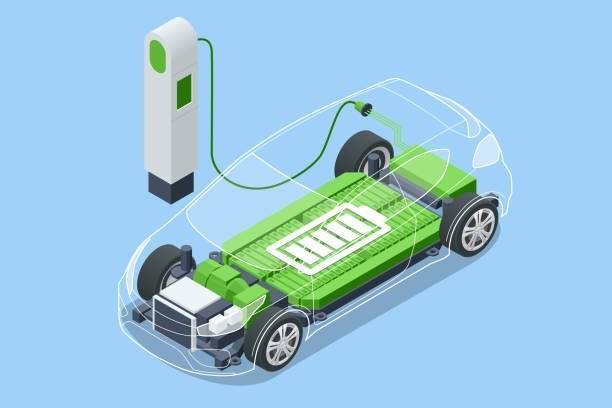

The electric vehicle (EV) industry, once heralded as the future of transportation, now faces a significant hurdle: the microchip shortage. In this article, we’ll delve into the intricate web of challenges posed by the shortage, its impact on the EV sector, and the strategies being employed to navigate through this gridlock.

Unpacking the Microchip Shortage

The microchip shortage, triggered by a combination of factors including the COVID-19 pandemic, increased demand for consumer electronics, and supply chain disruptions, has sent shockwaves through the automotive industry. Microchips serve as the nerve center of modern vehicles, powering essential functions such as engine management, infotainment systems, and advanced driver-assistance features. With semiconductor supply unable to keep up with soaring demand, automakers are grappling with production bottlenecks, delays, and increased costs.

The Chokehold on EV Manufacturing

Electric vehicle manufacturers, in particular, find themselves in the crosshairs of the microchip shortage. EVs rely heavily on sophisticated electronic systems that require a higher number of microchips compared to traditional vehicles. Consequently, automakers are facing challenges in meeting production targets, leading to delayed deliveries and potential setbacks in the EV market’s growth trajectory. Notably, Tesla, a leading player in the EV space, has reported difficulties in fulfilling orders due to chip shortages, underscoring the severity of the crisis for EV manufacturers.

Necessity Breeds Innovation

Amidst the gridlock, innovation emerges as a beacon of hope for EV manufacturers. Automakers are deploying various strategies to mitigate the impact of the microchip shortage, including prioritizing critical vehicle models, exploring alternative sourcing options, and even redesigning vehicles to use fewer chips temporarily. Additionally, collaborations across the industry and investments in semiconductor manufacturing capacity are being pursued to build resilience against future disruptions.

Navigating the Road Ahead

While the microchip shortage poses significant challenges for the EV industry, it also presents an opportunity for adaptation and transformation. As automakers navigate the uncertain terrain, consumers may experience delays in EV deliveries and potential changes to vehicle specifications. However, the underlying momentum behind the shift towards electric transportation remains strong, driven by environmental concerns, regulatory incentives, and technological advancements.

FAQs:

How long is the microchip shortage expected to last?

The duration of the microchip shortage is uncertain and contingent on various factors, including global semiconductor production capacity and the resolution of supply chain disruptions.

Which electric vehicle models are most affected by the chip shortage?

Electric vehicles with sophisticated electronic systems, such as Tesla’s Model S and Model X, are particularly susceptible to the microchip shortage.

How are automakers addressing the chip shortage?

Automakers are implementing diverse strategies, including prioritizing critical vehicle models, diversifying chip suppliers, and exploring alternative sourcing options to mitigate the shortage’s impact.

Will the chip shortage affect EV prices?

The chip shortage may lead to temporary price increases for electric vehicles as automakers grapple with production constraints and elevated manufacturing costs. However, long-term pricing dynamics will hinge on supply chain dynamics and market demand.

What can consumers do to minimize the impact of the chip shortage on EV purchases?

Consumers interested in purchasing electric vehicles should stay informed about production updates from manufacturers and consider placing orders in advance to secure their preferred models amidst potential supply constraints.