Charging Forward: EV Manufacturers Grapple with Microchip Shortage

Microship shortage in EV industryTable of Contents

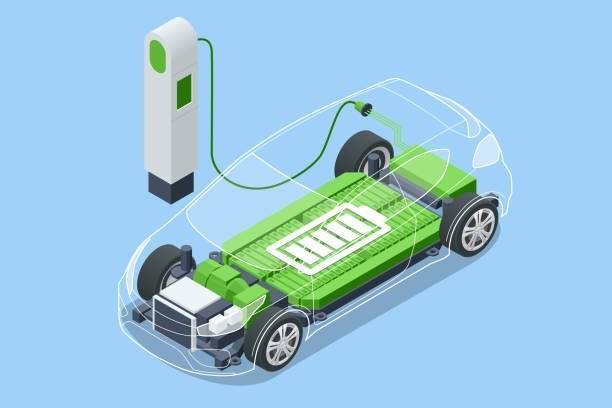

In the realm of electric vehicles (EVs), the road to innovation has encountered a significant speed bump: the microchip shortage. As the automotive industry undergoes a profound transformation toward electrification, manufacturers face the formidable challenge of navigating through the complexities of semiconductor scarcity. In this article, we delve into the impact of the microchip shortage on EV production and explore strategies adopted by manufacturers to overcome this hurdle.

Understanding the Microchip Shortage

The microchip shortage, stemming from various factors including supply chain disruptions, increased demand for consumer electronics, and geopolitical tensions, has sent shockwaves across industries reliant on semiconductor components. EV manufacturers, heavily dependent on microchips for critical functions such as battery management, powertrain control, and advanced driver-assistance systems (ADAS), find themselves at the epicenter of this crisis.

Impact on EV Production

- Production Delays: The microchip shortage has forced EV manufacturers to slow down production lines or halt assembly altogether, resulting in delays in delivering vehicles to customers.

- Supply Chain Disruptions: The intricate global supply chain network of EV components is strained as semiconductor suppliers struggle to meet demand, leading to bottlenecks in production.

- Increased Costs: Manufacturers are grappling with rising costs due to expedited shipping, sourcing from alternative suppliers, and idle production facilities, putting pressure on profit margins.

Strategies to Mitigate the Shortage

- Diversification of Suppliers: EV manufacturers are diversifying their supplier base to reduce reliance on a single source for microchips, thereby mitigating the impact of supply chain disruptions.

- Prioritization of Critical Systems: Companies are prioritizing the allocation of limited microchip supplies to essential systems within EVs, ensuring that key functionalities remain intact.

- Optimization of Production Processes: Streamlining production processes and optimizing inventory management help conserve microchip usage and minimize waste, maximizing efficiency amid shortages.

Innovations in EV Technology

Despite the challenges posed by the microchip shortage, the EV industry continues to innovate and adapt. Manufacturers are investing in research and development to enhance semiconductor efficiency, explore alternative materials, and develop advanced manufacturing techniques, fostering resilience in the face of adversity.

In conclusion, the microchip shortage poses a formidable challenge to EV manufacturers, disrupting production processes and testing the industry’s resilience. However, through strategic adaptation, technological innovation, and collaborative efforts, the EV sector remains committed to charging forward towards a sustainable and electrified future.

FAQs:

How long is the microchip shortage expected to last?

While predictions vary, experts suggest that the microchip shortage could persist for several more months or even extend into 2025, depending on factors such as supply chain resilience and global economic conditions.

How are EV manufacturers prioritizing microchip allocation?

EV manufacturers prioritize microchip allocation based on critical systems such as battery management, powertrain control, and safety features like ADAS, ensuring that essential functionalities are maintained.

Are there any long-term solutions to prevent future shortages?

Long-term solutions include diversification of supplier networks, investment in domestic semiconductor manufacturing, and collaborative efforts to enhance supply chain resilience and transparency.

How are consumers affected by the microchip shortage?

Consumers may experience longer wait times for EV deliveries, limited vehicle options due to production constraints, and potential price increases as manufacturers pass on increased costs.

What can consumers do to mitigate the impact of the shortage?

Consumers can stay informed about production updates from manufacturers, consider alternative vehicle options if faced with delays, and communicate with dealerships for personalized assistance.