The Power Drain: How Microchip Shortage is Hitting Electric Vehicle Production

Microship shortage in EV industryTable of Contents

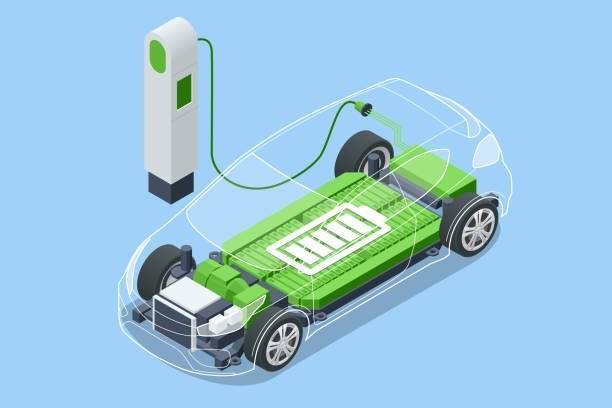

In the realm of electric vehicles (EVs), a critical challenge has emerged: the microchip shortage. As semiconductor supply constraints disrupt production lines, the EV industry faces significant setbacks. In this article, we delve into the impact of the microchip shortage on electric vehicle production and explore strategies employed to mitigate its effects.

Unveiling the Microchip Shortage

Microchips, essential components powering the technological advancements in EVs, are in short supply. This shortage, caused by a confluence of factors including increased demand, supply chain disruptions, and geopolitical tensions, poses a significant threat to the electric vehicle ecosystem.

The Toll on EV Production

- Production Bottlenecks: EV manufacturers are grappling with production bottlenecks and assembly line disruptions due to the microchip shortage. Delays in vehicle delivery and reduced output have become commonplace, hampering the industry’s growth trajectory.

- Supply Chain Strain: The intricate global supply chain network that sustains EV production is under strain. Semiconductor suppliers struggle to meet demand, leading to supply shortages and heightened competition for limited chip supplies.

- Financial Impact: The microchip shortage exerts financial pressure on EV manufacturers. Rising costs associated with expedited shipping, alternative sourcing, and idle production facilities eat into profit margins, exacerbating the crisis.

Strategies for Mitigating the Shortage

- Diversification of Suppliers: EV companies are diversifying their supplier base to mitigate dependence on a single source for microchips. By spreading risk across multiple suppliers, companies aim to minimize the impact of supply chain disruptions.

- Prioritization of Functions: In response to limited chip availability, manufacturers prioritize the allocation of microchips to critical functions within EVs. Essential systems such as battery management and safety features take precedence to ensure vehicle performance and integrity.

- Efficiency Optimization: Optimizing production processes and conserving microchip usage through efficient inventory management are crucial strategies. Lean manufacturing principles and technological innovations help maximize output amidst supply constraints.

Innovating Through Adversity

Despite the challenges posed by the microchip shortage, the EV industry remains resilient and innovative. Companies continue to invest in research and development, exploring alternative materials, chip architectures, and manufacturing techniques to mitigate the impact of semiconductor shortages.

In conclusion, the microchip shortage poses a significant challenge to the electric vehicle industry, disrupting production processes and testing the resilience of manufacturers. However, through strategic adaptation, innovation, and collaborative efforts, the EV sector remains committed to overcoming this obstacle and driving forward towards a sustainable and electrified future.

FAQs:

How long is the microchip shortage expected to last?

The duration of the microchip shortage is uncertain, with estimates ranging from several months to potentially years, depending on supply chain dynamics and global economic conditions.

How are EV manufacturers managing production delays caused by the shortage?

EV manufacturers are adjusting production schedules, prioritizing critical functions, and exploring alternative sourcing strategies to mitigate the impact of microchip shortages on production timelines.

Are certain types of EVs more affected by the microchip shortage than others?

While all EVs rely on microchips for various functions, models equipped with advanced features such as autonomous driving capabilities may face greater challenges due to their complex semiconductor requirements.

How does the microchip shortage affect consumer options and pricing for EVs?

Consumers may experience limited availability of certain EV models, longer wait times for delivery, and potential price increases as manufacturers grapple with production constraints and rising costs.

What steps can consumers take to mitigate the impact of the shortage on their EV purchase?

Consumers are encouraged to stay informed about production updates from manufacturers, consider alternative vehicle options, and communicate with dealerships for personalized assistance and guidance.