Wheels Stuck in Place: The Microchip Dilemma in the EV Market

Microship shortage in EV industryTable of Contents

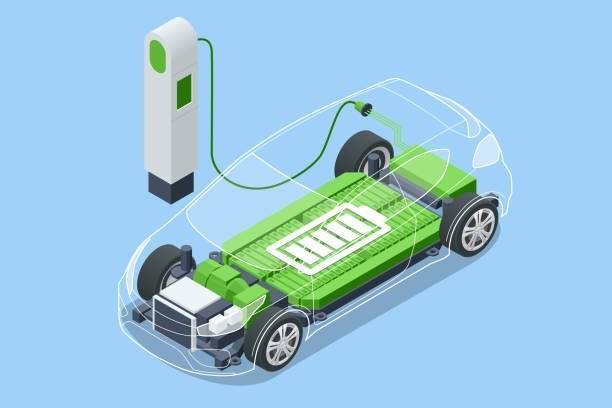

In the fast-moving world of electric vehicles (EVs), a significant obstacle has emerged, causing wheels to grind to a halt: the microchip dilemma. This unexpected challenge has reverberated through the EV market, disrupting production and challenging the industry’s growth trajectory. In this article, we’ll explore the intricacies of the microchip shortage in the EV market, its impact, and potential solutions.

Unraveling the Microchip Dilemma

Microchips, the silent powerhouses driving the technological advancements in EVs, have become a scarce resource. This shortage, stemming from a combination of factors such as increased demand, supply chain disruptions, and geopolitical tensions, has created a bottleneck in the production of electric vehicles.

The Impact on EV Production

- Production Delays: The microchip shortage has caused significant delays in the production of EVs. Manufacturers are struggling to procure an adequate supply of microchips, leading to disruptions in assembly lines and extended lead times for customers.

- Supply Chain Strain: The global supply chain network supporting EV production is under strain. Semiconductor suppliers are unable to meet the surging demand, resulting in shortages that ripple through the entire manufacturing process.

- Innovation Setbacks: The microchip shortage poses challenges to innovation within the EV market. Research and development efforts aimed at improving vehicle performance and introducing new features are hampered by the scarcity of semiconductors, slowing down progress in the industry.

Strategies for Mitigation

- Supply Chain Optimization: EV manufacturers are optimizing their supply chains to mitigate the impact of semiconductor shortages. Diversifying supplier networks, implementing robust inventory management systems, and prioritizing critical components are key strategies to navigate through the crisis.

- Agile Manufacturing Practices: Flexibility is crucial in overcoming production challenges posed by the microchip shortage. EV manufacturers are adopting agile manufacturing practices, adjusting production schedules, and exploring alternative sourcing strategies to maintain operational continuity.

- Investment in Innovation: Despite the challenges, the EV industry remains committed to innovation. Companies continue to invest in research and development, exploring alternative materials, chip architectures, and manufacturing techniques to address semiconductor shortages and drive progress.

Navigating Towards Solutions

In the face of adversity, the EV market is mobilizing resources and expertise to find solutions to the microchip dilemma. Collaborative efforts between manufacturers, suppliers, and policymakers are underway to address supply chain vulnerabilities and chart a path forward. From optimizing production processes to investing in domestic semiconductor manufacturing, the industry is actively pursuing strategies to overcome this challenge.

In conclusion, the microchip dilemma presents a significant challenge to the EV market, disrupting production processes and innovation. However, through strategic adaptation, collaboration, and investment in innovation, the sector remains resilient and committed to overcoming this obstacle and driving forward towards a sustainable and electrified future.

FAQs:

How long is the microchip shortage expected to last?

The duration of the microchip shortage is uncertain, with estimates ranging from several months to potentially years, depending on various factors such as supply chain dynamics and market forces.

How are EV manufacturers managing production delays caused by the shortage?

EV manufacturers are adjusting production schedules, prioritizing critical functions, and exploring alternative sourcing strategies to mitigate the impact of microchip shortages on production timelines.

Are certain types of electric vehicles more affected by the microchip shortage than others?

While all electric vehicles rely on microchips for various functions, models equipped with advanced features such as autonomous driving capabilities may face greater challenges due to their complex semiconductor requirements.

How does the microchip shortage affect consumer options and pricing for electric vehicles?

Consumers may experience limited availability of certain EV models, longer wait times for delivery, and potential price increases as manufacturers grapple with production constraints and rising costs.

What steps can consumers take to mitigate the impact of the shortage on their electric vehicle purchase?

Consumers are encouraged to stay informed about production updates from manufacturers, consider alternative vehicle options, and communicate with dealerships for personalized assistance and guidance.